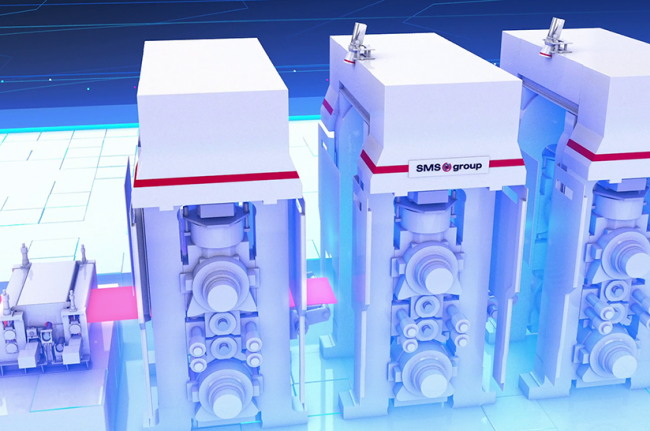

Salzgitter: „Salcos“ nun offizielle Grünstahl-Marke

Der Salzgitter-Konzern vertreibt seine CO2-reduzierten Stahlprodukte ab sofort offiziell unter dem Namen „Salcos“. Mit der neuen Markenführung will man sich eng an der Kategorisierung des Low Emission Steel Standard (LESS) der WV Stahl orientieren.

Details