The off-gas from the recycle cyclone of the CFB reactor is passed through a process gas heat exchanger and a multiclone to recover ultrafine dust particles, which are recycled. The off-gas is then scrubbed and quenched simultaneously to remove any dust and water produced during the reduction. The cooled and cleaned process gas is then recompressed and subsequently preheated to a temperature of approximately 750 °C before being reintroduced into the reactor system.

Further, a significant advantage of the CFB reactor is the ability to inject dust-laden, partially reacted gas from the second-stage FB reactor, which creates a counter-current flow of gas and solids throughout the dual-reactor system. This has two advantages: the nozzle grate of the CFB reactor is only exposed to clean recycled process gas, thereby minimizing nozzle wear, and the overall gas utilization of the entire process is maximized. The Circored process generates no residues or relevant emissions besides water.

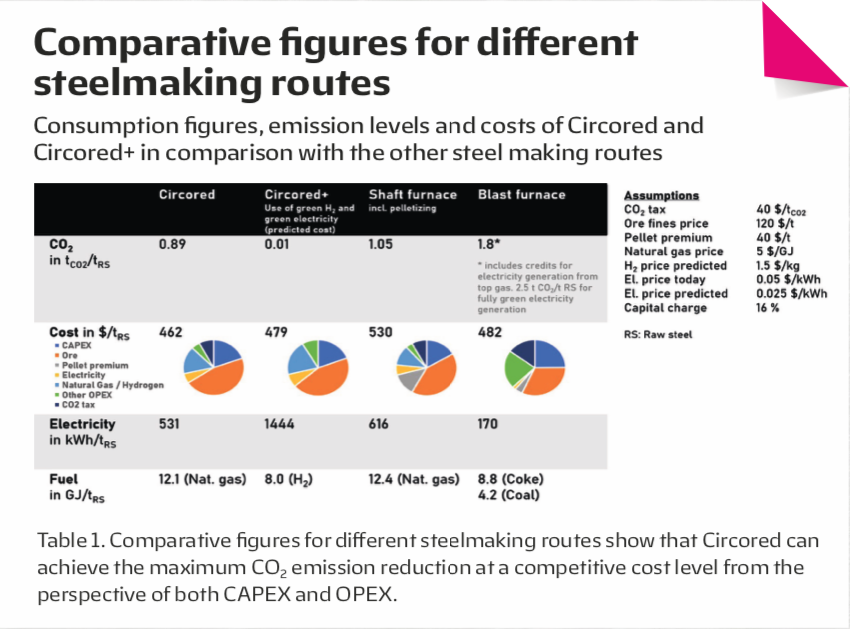

Comparison of different steelmaking routes

Looking at the Circored/EAF steelmaking route versus other state-of-the-art routes, especially in terms of CO2 emissions and cost, common battery limits need to be defined. We look here at the conversion of iron ore concentrate to crude steel with all the required intermediate steps, forming the reference for this comparison (see Figure 4). Both Circored and shaft furnace direct reduction technologies produce DRI or HBI that can be used directly in an EAF. The product from the blast furnace, pig iron, is fed to an oxygen converter (BOF). These downstream processes are intentionally considered here in the CO2 and cost figures.

If an ultrafine concentrate is used, a microgranulation step should be applied to make the material particle size distribution applicable to fluidization. Along with this option comes the opportunity to recycle any kind of dust or fines originating at different points in the plant. As default option the Circored process uses a natural gas reformer to provide hydrogen for the reduction. For future scenarios, we further included a Circored+ process variant that applies blue or green hydrogen produced from renewable sources for direct reduction as well as electrical heaters for drying and preheating.

Table 1 summarizes the resulting figures for the compared steelmaking routes. It is apparent that the BF/BOF route is by far the largest emitter of CO2; furthermore, the technical solutions to minimize emissions are limited for this route. While the CO2 emissions of the Circored process and shaft furnace direct reduction are in the same order of magnitude, Circored benefits from the omission of the pelletizing step. As the Circored+ process is designed to produce fully green steel, its CO2 emissions are negligible.

When it comes to cost, Circored is the most advantageous route, partly because the CO2 taxation costs are lower than for the BF/BOF route and because there is no burden of a pellet premium price (compared to the shaft furnace route). For the purposes of this calculation the pellet premium price, which is subject to unavoidable fluctuations, was cautiously assumed to be as low as USD 40/t. The Circored+ process variant requires an estimation of future green hydrogen and green electricity costs, which have conservatively been assumed to be 150% for hydrogen and 125% for electricity of the costs predicted by the International Renewable Energy Agency (IRENA) [1]. Consequently, in terms of CO2 emissions and cost, the ‘regular’ Circored process is already preferable today, and the Circored+ variant, with close to zero emissions, is predicted to be on the same production cost level once renewable energy becomes more cost competitive.