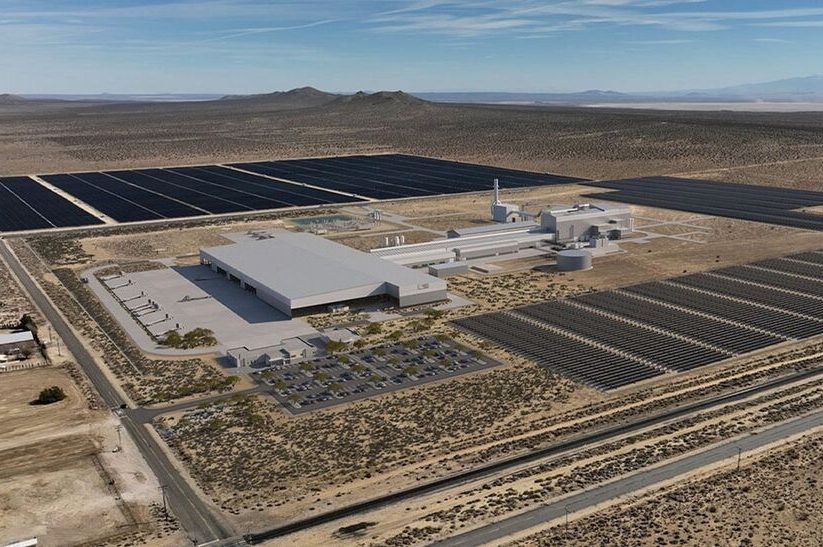

USA leading rebar fabricator Pacific Steel Group (PSG) awarded Danieli a contract to supply a MIDA Hybrid minimill in Mojave, California. The new plant will produce 380,000 shtpy of straight and spooled rebar in the most efficient and ecological way.

Fed by a continuous charge system, the scrap will be processed through DigiMelter and LF digital melting and refining units, powered by the Q-One digital power feeder which ensures the best power conditions at different frequencies. Liquid steel will be transformed into finished products in just 10 minutes by using QLP-DUE technology featuring a single-strand Octocaster feeding a rolling mill in endless casting-rolling mode. In addition to power and process control systems and robotics, Danieli Automation will also provide the Q3-Met manufacturing execution system for production scheduling and tracking, for maximum plant efficiency.

Q-Sym and Q3-Dyms –automatic scrap and yard management systems– together with ladle tracking system have been also chosen by Pacific Steel Group for full tracking of products and steel. Thanks to such features, the relevant over-head cranes are automated in the three key technological areas of scrap feeding, ladle handling and storage of the rolled product.

Robotic solutions will be applied to the DigiMelter and LF sampling, furnace EBT and final product marking, increasing operator safety and execution repetitiveness. Finally, advanced automation featuring digital smart casting and rolling, automatic gap control, smart pinch rolls and tail brakers are also included in the design.

Developed by Danieli Automation, Q-Jenius will allow the electrical feeding of DigiMelter, ladle furnace, Q-Heat induction heaters, rolling mill stand motors and fume-treatment plant fans, directly from the solar field.

Find more english news > here.