TMCP steel plates: Mechanical Properties Level

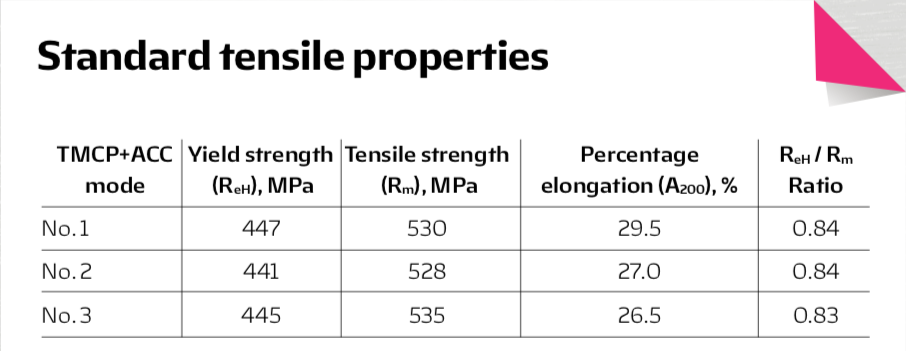

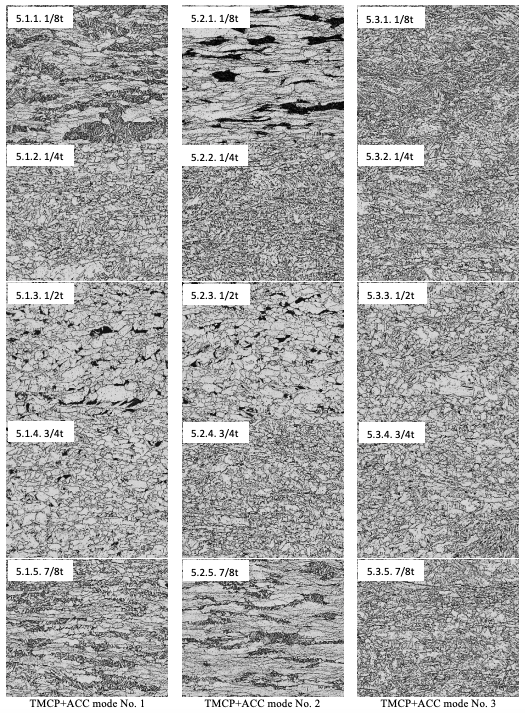

The strength level (Table 3) of the studied S420ML steel 100 mm in thickness measured on round-section samples taken from 1⁄4 thickness of heavy plates in accordance with the EN 10025-1:2019 requirements meets the requirements as specified in Table 2. Results provided in Table 3 allow to conclude that the three studied TMCP+ACC modes have shown roughly the same results. This is quite explicable considering the fact that the microstructure of all the three studied heavy plates in 1⁄4 thickness (where the tests were conducted) was identical (Figures 5.1.2, 5.2.2 and 5.3.2) and had the form of a dispersed mixture of ferrite and bainite. However, despite the fact that the results of the acceptance (in 1⁄4 thickness) tests were the same, the mechanical properties of plate’ layers in different thickness will be heterogeneous, which is primarily due to the different microstructural condition of plate produced under different temperature and cooling modes of TMCP+ACC.

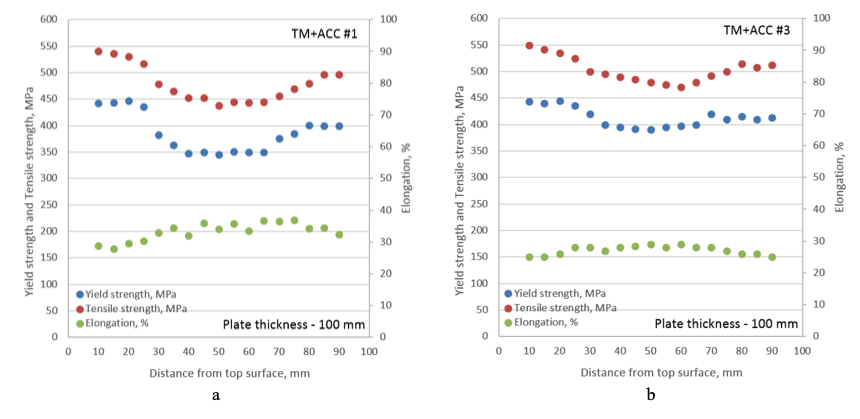

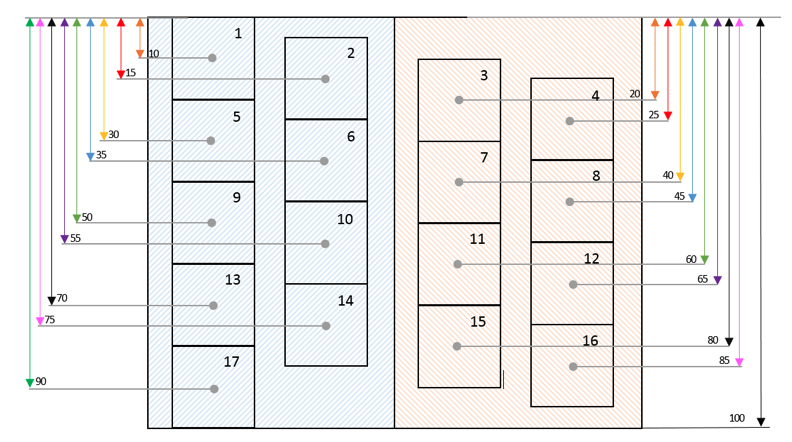

In order to determine the level of strength properties in different thickness layers of the studied plates under TMCP+ACC modes No. 1 and No. 3, additional investigation tests were carried out on round-section samples in accordance with the sampling plan in Figure 6. The axis of the first and the last samples in the set is 10 mm away from the top and the bottom surfaces. Due to the step-by-step arrangement, the through thickness testing interval is 5 mm.

Despite the fact that the results of the acceptance (in 1⁄4 thickness) tests (Table 3) were the same, the mechanical properties of layers of diverse thickness were heterogeneous in heavy plates produced under TMCP+ACC modes No. 1 (plate no. 1) and No. 3 (plate no. 3), which is primarily due to the different through thickness microstructural conditions of steel (Figure 5).

Figure 5. Microstructure of 100 mm S420ML heavy plates from low-carbon microalloyed steel after three different TMCP+ACC modes (x200)

The top layer (up to 25 mm) of plate No. 1 is characterized by ReH values of 436 – 442 MPa and Rm from 517 – 540 MPa (Figure 7a). Further, from 26 mm to 50 mm of thickness, there is a significant reduction in ReH to the minimum registered value of 345 MPa and Rm to 438 MPa. In the bottom thickness area from 76 to 100 mm, the ReH and Rm levels increase to reach 385 – 401 MPa and 470 – 497 MPa, respectively. The differences in ReH and Rm fully reflect the patterns of changes in the microstructural condition of the studied heavy plates shown in Figures 5.1.1–5.1.5. The arithmetic mean of ReH of heavy plate No. 1 is 386 MPa, Rm is 479 MPa.

The main difference in the results of strength investigation for plates produced under TMCP+ACC mode No. 3 (plate no. 3) is the level of ReH and Rm in the midthickness thickness layers. At thickness range from 26 to 50 mm, ReH remains not lower than 390 MPa and Rm lower than 480 MPa. The average ReH value of plate no. 3 is 413 MPa, Rm 503 MPa. This level corresponds to the microstructural condition described in Figures 5.3.1–5.3.5.

Acceptance tests of longitudinal impact energy in 1/4 of thickness of plate no. 1 showed the following results: KVLav-20 323 J, KVLav-40 105 J and KVLav-50 54 J. Impact energy of plate no. 3: KVLav-20 322 J, KVLav-40 235 J and KVLav-50 114 J. The difference in the level of impact energy between plate no. 1 and no. 3 is also significant, as it largely depends on the microstructure of the tested layer. The result of the investigation of impact test results will be provided in future publications. No significant differences were found in Z-test results of plate no. 1 and no. 3. In both cases the reduction of area ψz did not go below 45%.

Figure 6. Sampling procedure for heavy plates 100 mm in thickness for investigation of tensile properties in different thickness layers